SAN Corecell und Kerdyn Green PET bieten sie eine ideale Möglichkeit, um Strukturen zu bauen, die höchsten Anforderungen entsprechen. In diesem Artikel zeigen wir Ihnen, wie Sie Flachsfaser in Kombination mit Kernmaterialien einsetzen können, um umweltbewusster und gleichzeitig kosteneffektiver zu bauen.

In boatbuilding and other industries that rely on lightweight yet robust materials, glass, carbon and flax fibers play an important role. Combined with core materials such as PVC, SAN Corecell and Kerdyn Green PET, they offer an ideal way to build structures that meet the most demanding requirements. In this article, we will show you how you can use flax fiber in combination with core materials to build more environmentally conscious and at the same time more cost-effective.

How to build more environmentally conscious and at the same time more cost-effective by using flax fiber

Flax fiber is a sustainable alternative to conventional fiber materials such as glass and carbon fibers. It is derived from the hemp plant and is biodegradable. Flax fiber is also extremely lightweight and has high strength and stiffness. However, it tends to be a bit more expensive than glass and carbon fibers.

However, when you combine flax fiber with core materials, you can not only build more environmentally conscious, but also more cost-effective. Flax fiber is compatible with all common core materials and can come in a variety of thicknesses and sizes, depending on your requirements.

By combining flax fiber with core materials, you can save weight and costs without sacrificing quality and performance. In addition, using flax fiber improves the environmental footprint of your project.

It’s important to use high-quality materials to ensure that your boats can withstand the challenges on the water. At the same time, however, it’s also important to keep the environmental impact of your products in mind. That’s where our ampliTex™ and powerRibs™ natural fiber solutions come in.

These sustainable fiber materials not only offer environmentally friendly alternatives to traditional materials such as glass and carbon fibers, but also offer novel design possibilities and excellent vibration damping. Flax fibers used to make our solutions are biodegradable and have a CO2-neutral footprint throughout their lifecycle. In addition, ampliTex™ and powerRibs™ have similar properties to carbon fibers and are compatible with all common core materials. This allows you to save weight and costs without sacrificing quality and performance.

Thanks to our many years of experience in the development of natural fiber solutions and cooperation with our partners, we can offer you a wide range of products suitable for various applications. Whether for boat building, motorsports or other applications, our fiber solutions offer a sustainable alternative to conventional materials.

AmpliTex: Advanced technology for high-quality composites

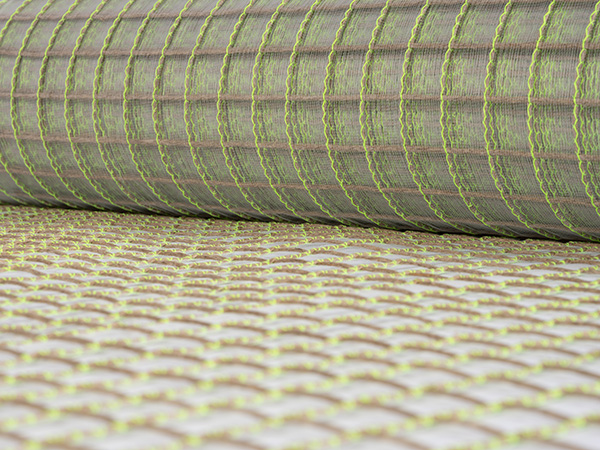

The AmpliTex™ range is a product range consisting of high-performance reinforcing materials made from natural fibers. The use of flax fibers offers a number of advantages over conventional reinforcing materials. High vibration damping, specific bending stiffness and fatigue resistance are just some of the properties that distinguish AmpliTex™. AmpliTex™ also sets new standards in terms of design options, as natural translucency and radiotransparency are possible in addition to dyeing.

The fabrics in the AmpliTex™ range include various weaves and are optimized for lightweight reinforcement. Thanks to excellent mechanical properties and low environmental impact, AmpliTex™ is extremely versatile. Whether in sports, automotive, aerospace or marine applications, AmpliTex™ offers outstanding performance. It is available as a dry fiber or as a finished laminate and can be used in a variety of manufacturing scenarios. Thermoplastic for efficient production in large-scale applications or thermoset with vacuum infusion or RTM or as a finished laminate in autoclave or prepreg compression molding (PCM) for high-performance applications such as motorsport bodies, aerospace or space applications.

Flax fiber quality, yarn thickness and twisting are all highly engineered to achieve optimal mechanical properties in the final composite part. With its unique properties and design options, AmpliTex™ is a good choice for those who demand the highest standards from their reinforcing fabrics.

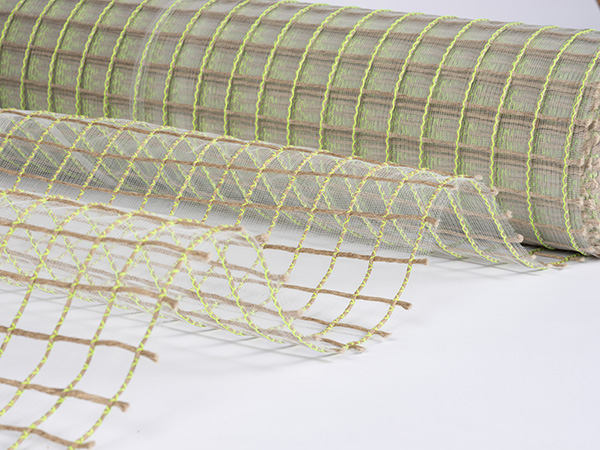

PowerRibs: Natural fiber reinforcement for high-performance applications

Nature provides us with amazing solutions to produce high-performance materials even in the high-tech industry. One such solution is powerRibs™, which is an extremely lightweight but high-performance lattice made from natural fiber reinforcement. Inspired by leaf veins, powerRibs™ gives a thin-walled shell maximum resistance with minimum weight. A 3D structure on one side of the element allows less base material to be used, reducing cost, consumption and weight in production.

The result is impressive: a doubling of bending stiffness and an improvement in vibration damping of up to 250%, while reducing weight. The flax fiber quality, yarn thickness and twist are all highly engineered for optimal mechanical properties in the final composite. The use of European flax and continuous monitoring of the fiber blend ratio ensure consistent quality over time.

When combined with ampliTex™ engineered fabrics, the result is a complete natural fiber layer that achieves the performance of carbon fibers. powerRibs™ are also ideal for reinforcing carbon fibers and glass fibers. PowerRibs™ not only offer improved performance, but also an environmentally friendly solution for the high-tech industry.

PowerRibs: Natural fiber reinforcement for high-performance applications

Flax fibers are a natural fiber obtained from the stems of the hemp plant. They are often used as an alternative to synthetic fibers such as carbon or glass fibers because they are biodegradable and have a lower environmental impact.

No, flax fiber is usually not as strong as glass and carbon fibers. However, flax fiber has the advantage of being very light and stiff and has a high energy absorption capacity. In addition, flax is a sustainable alternative to glass and carbon fibers because it is derived from a renewable plant and therefore has a lower environmental impact. Flax is therefore ideal for applications where weight reduction and sustainability play an important role.

Yes, flax fiber is compatible with all common core materials.

PowerRibs are natural fiber reinforcement. They are an extremely lightweight, high-performance grid of natural fiber reinforcement that creates a 3D structure on one side of the element. PowerRibs can triple the bending stiffness, reducing material consumption and weight.

The AmpliTex range consists of extremely lightweight, high-performance reinforcement fabrics made from natural fibers. They include different weaves with little or no crimp and twist, optimized for lightweight reinforcement. Excellent mechanical properties and low environmental impact make AmpliTex reinforcing fabrics extremely versatile.

Conclusion

Combining flax fiber with core materials such as PVC, SAN Corecell and Kerdyn Green PET offers an ideal way to build more environmentally conscious and cost effective. Flax fiber is a sustainable alternative to traditional fiber materials such as glass and carbon fibers and offers high strength and stiffness. By using flax fiber, you can save weight and cost without sacrificing quality and performance.

Using flax fiber in combination with core materials is a great way to build more environmentally conscious and cost effective. Flax fiber offers high strength and stiffness and is compatible with all common core materials. Visit our online store now