Table of Contents

Wide range of applications!

Our GRP profiles have high strength, light weight and outstanding durability. This makes them a premium alternative to traditional materials such as concrete, aluminum and wood. See here how we have helped others implement future-proof GRP solutions in areas such as bridges, platforms and access routes, as well as stairs and handrails.

Platforms for maritime environments

The fact that fiberglass profiles and gratings require no maintenance and do not corrode makes them the choice for maritime environments. FRP products have a proven track record in applications in and around salt water. Therefore, jetties and the platforms in harbors are increasingly equipped with corrosion-resistant composite profiles and gratings.

Durable GRP bridges

With GRP bridges, you get a strong and lightweight structure that can be easily fabricated and assembled on site using ordinary tools. In addition, GRP bridges have a long service life and are maintenance-free. These are factors that make GRP bridges a more sustainable and future-proof solution. By combining these advantages, the wide range of fiberglass profiles and decking components can be used for all types of bridges.

Stairs & handrails with GRP

The stair and handrail systems have proven themselves in the construction industry, combining high strength and light weight with corrosion resistance. This makes our stair and handrail system an excellent and cost-effective alternative to conventional materials such as wood, steel and aluminum. The material is virtually maintenance-free and a life expectancy of over 100 years is not uncommon.

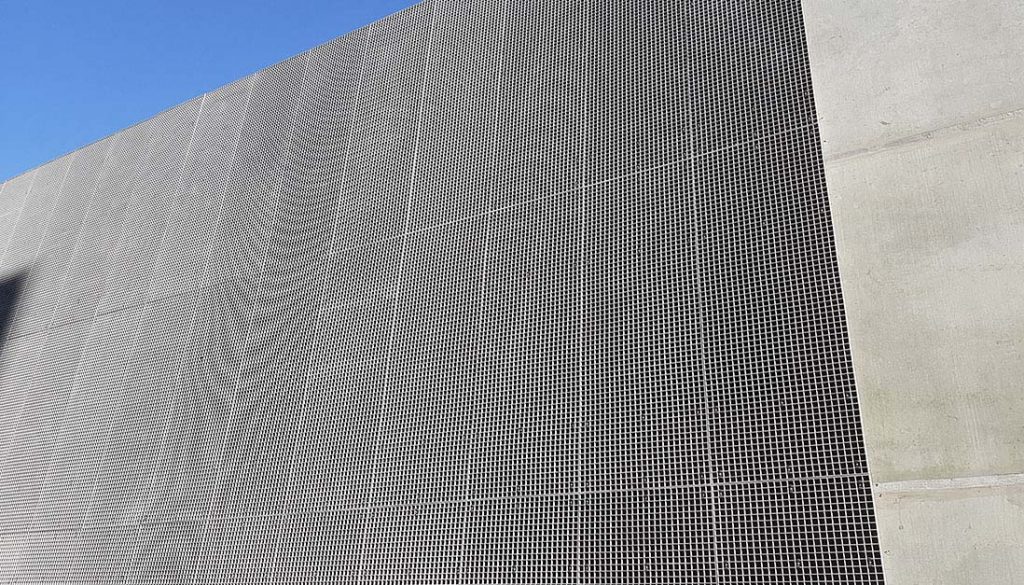

Cladding with GRP gratings

Fiberglass grating can be used as part of the facade to create an exciting play with light while meeting the building’s weight restrictions. This is because the GRP material is lighter than traditional materials such as concrete. It is also durable and requires no maintenance.

Industrial platforms

Durable and corrosion-resistant GRP grids, planks and profiles are particularly suitable for industrial platforms in demanding environments because they do not rust or rot. In addition, the lightweight composite material is easy to adapt on site, requires minimal maintenance and is non-conductive. The platforms also have non-slip surfaces and are equipped with CTM’s Industrial Railing System to ensure better safety.

Advantages of pultruded glass fiber

NO CORROSION

Excellent resistance to aggressive chemicals, environmental influences and unlike metals, electrolytic corrosion.

HIGH STRENGTH

Strong as steel, high glass fiber content and very low water absorption of approx. 3%. This ensures stable properties.

LIGHT WEIGHT

Only a quarter of the weight of steel and about half that of aluminum — resulting in lightweight designs, ease of handling and cost-effective transportation.

ELECTRICAL INSULATION

Non-electrically conductive — thus reducing the complexity of grounding, e.g. in railroad applications.

THERMAL INSULATION

A heat transfer coefficient far below that of steel or aluminum contributes to an energy-efficient end product.

LITTLE OR NO MAINTENANCE

Excellent durability ensures long service life with minimal maintenance requirements. UV protection due to outer layer.

EASY TO PROCESS

Normal power tools can be used for processing GRP. As with hardwood, hardened steel drill bits and diamond-coated saw blades are recommended.

SUSTAINABLE MANUFACTURING

The energy-saving manufacturing process and ISO 14001 energy certification enable sustainable end products. The glass fiber waste is used as a substitute material in cement production.

GRP — building materials of the future!

GRP is a plastic-based composite material. This means that the material is made of one or more substances that together create a unique material that is custom-made for a specific purpose.

Our fiberglass profiles are made of dry glass fibers and a liquid matrix, usually a thermoset polyester. The slightly more technical term is glass fiber reinforced polymer. However, the most common designations are fiberglass or GFRP. Individually, these two substances are not suitable for use in structures, but together they make an exceptionally strong and rigid material that is often a more cost-effective and sustainable alternative to conventional building materials — literally tailor-made for the construction of the future.

Our products

Due to its lightness, strength and durability, GRP opens up possibilities for sophisticated, intelligent final designs. Unlike conventional materials, the material properties of pultruded GRP profiles can be customized. The profiles can thus be adapted to the application and customer needs, e.g. in the construction, offshore and industrial sectors.

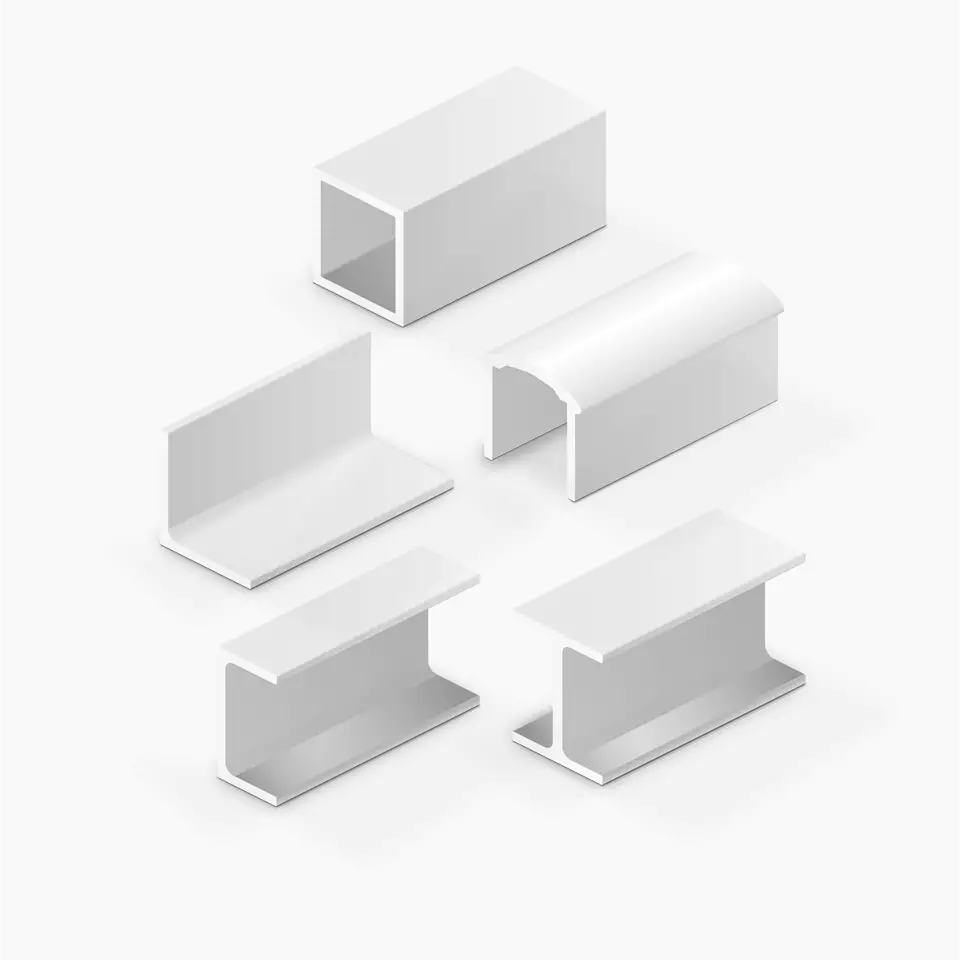

GRP profiles are corrosion resistant and an economical alternative to concrete, wood, steel and aluminum. The profiles have a long service life, avoiding the cost of expensive replacement of elements. Our wide range includes U profiles, I profiles, angle profiles, square tubes, flat profiles, railing profiles and accessories such as fittings, bolts and screws.

Our GRP profiles have the strength of steel, but the density is only a quarter. This allows a weight saving on the GRP components. This usually leads to savings in construction costs, both for special tools and for the personnel and assembly time, which can affect other operations.

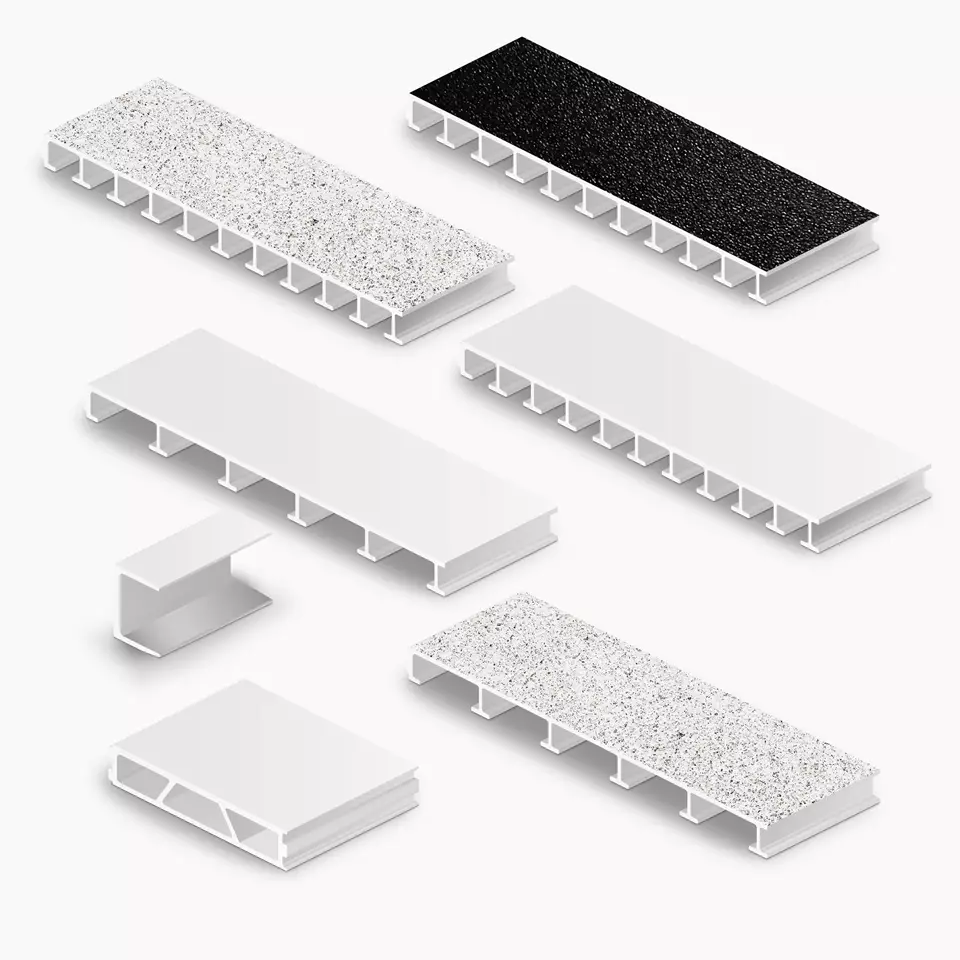

With our GRP planks you get a cost-effective alternative to traditional covers, planking or bridge decking. The planks are ideal for reducing the weight of the final structure without compromising the required strength. The light weight also reduces construction costs, such as labor and special machinery. Our planks are suitable for different load requirements. Due to their relatively high strength, GRP planks are very suitable for bridge decks, covers and planking. It is possible to realize constructions with the strength of steel or concrete, but weighing considerably less. A clear advantage, because the transport of the solution from the place of assembly to the place of assembly becomes cheaper and the assembly is easier overall.

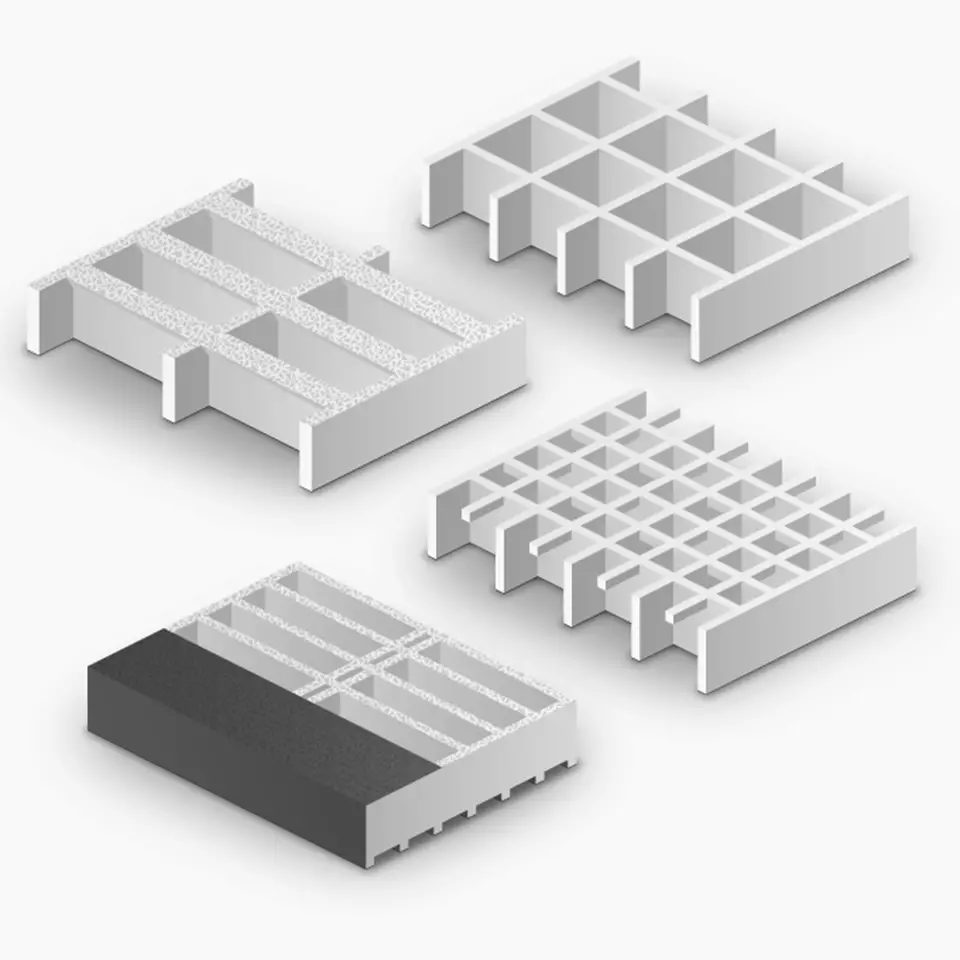

Our gratings are made of glass fiber reinforced plastic and are therefore durable and corrosion resistant. They are therefore ideally suited for demanding environments such as offshore, in the chemical industry, swimming pools and cooling towers. They are durable and do not rust — unlike steel. Our GRP gratings have a non-slip and durable surface. Since the non-slip surface does not affect the load-bearing capacity of the grates, they are ideal for use in industry.

Do you have a question for us? Our team is here for you. Contact us now for your individual project. We have a solution for almost everything! Give us a call: +49 4621 95533