Inhalt

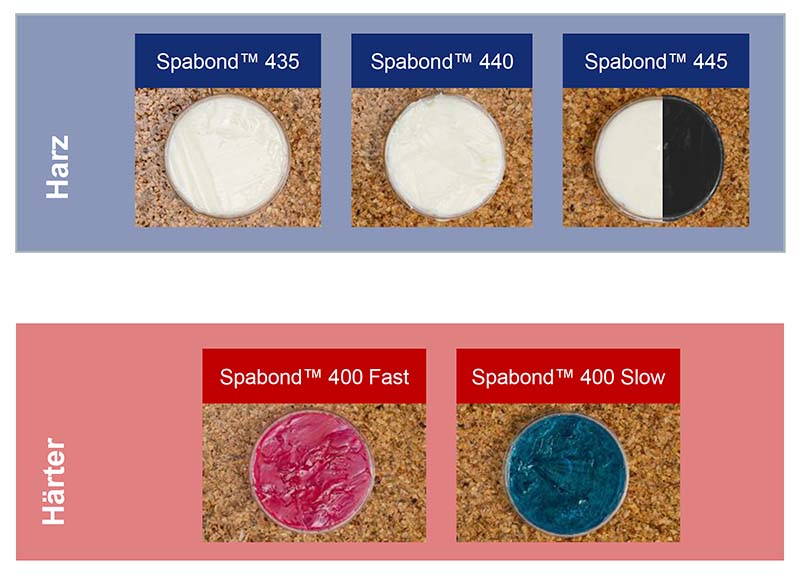

Introduction to Spabond™ 400

- Spabond™ 435: Ideal for thin bondlines such as core bonding, large surface areas and detailed work.

- Spabond™ 440: Optimised for rapid dispense from cartridges or automated mixing machines.

- Spabond™ 445: For large gap filling & filleting applications as well as high performance projects, with a black resin option available.

- Spabond™ 400FR: structural fire retardant epoxy adhesive

Why is Spabond™ 335, 340LV and 345 being replaced?

Spabond remains a key adhesive brand for Marine and industrial applications The Spabond™ 300 series is being replaced because:

- Opportunity to Improve handling and processing properties, dispensing & carbamation resistance

- Simplify the portfolio, moving from 13 to 5 components

- Improved Health & Safety

Spabond™ 400 offers customers the same benefits as the Spabond™ 300 series, with improved Health & Safety, application and performance advantages

What is changing?

Spabond™ 400 is a new product range that covers the full functionality of Spabond™ 335, 340 and 345. The simplified portfolio has 3 resins with increasing sag resistance.

- 10mm: SP335 = now SP435

- 20mm: SP340 = now SP440

- 30mm: SP345 = now SP445

All resins use the same 2 hardeners:

- Spabond™ 400 Fast: ½ hour working time

- Spabond™ 400 Slow: 3 ½ hour working time

- 6 hour thin film working time

- 15 hour clamp time

The Spabond™ 400 Range: Key Properties

| SYSTEM PROPERTIES AT 20°C | GAP FILLING | HARDENER | TYPICAL BEAD WORKING TIME | LAPSHEAR STRENGTH |

| Spabond™ 435 Ideal for thin bondlines such as core bonding, large surface areas and detailed work. | Up to 10 mm | Fast | ½ hour | 35 MPa |

| Slow | 3 ½ hours | 35 MPa | ||

| Spabond™ 440 Optimised for rapid dispense from cartridges or automated mixing machines. | Up to 20 mm | Fast | ½ hour | 39 MPa |

| Slow | 3 ½ hours | 37 MPa | ||

| Spabond™ 445 For large gap filling & filleting applications and high performance projects, with a black resin option available. | Up to 30 mm | Fast | ½ hour | 37 MPa |

| Slow | 3 ½ hours | 36 MPa | ||

| Spabond™ 400FR Structural fire retardant epoxy adhesive | Up to 20 mm | Fast | ½ hour | 39 MPa |

Benefits of Spabond™ 400

Spabond™ 400 Improved Handling & Application

Spabond™ 400 has been formulated to improve handling & application performance:

- Improved dispense and sag resistance recovery

- Improved manipulation & filleting performance

- Robust to high humidity application

Pproduct features chart

| SP 335 | SP 340 | SP 345 | SP 400 | |

| Manual dispense | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | ★★★★☆ |

| Sag resistance recovery | ★★☆☆☆ | ★★★★☆ | ★★★★★ | ★★★★★ |

| Surface wetting | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Manipulation / Filleting | ★★★☆☆ | ★★★☆☆ | ★★☆☆☆ | ★★★★☆ |

| High Humidity | ★★★★☆ | ★★★☆☆ | ★★★★☆ | ★★★★☆ |

Enhanced Curing Profile

Spabond™ 400 Series only has 2 hardener speeds: Fast and Slow

Spabond™ 400 Slow hardener combines the key characteristics of the Spabond™ 300 series Slow and Extra-Slow hardeners:

- Longest hardener thin film working time (SP345 Extra-Slow) of 6hrs

- Fastest overnight clamp time (SP340 Slow) of 15 hours

- This allows enough time to bond large structures whilst maintaining an overnight initial cure

Lapshear Strength (MPa) Adhesion Data

Comparable materials

Improved Health & Safety

The current 300 series hardeners contain substances of very high concern (SVHCs). Gurit Internal policy and external legislation mean these need to be removed or improved. Spabond™ 400 hardeners are low toxicity formulations:

- Improved Hazard Labelling

- Free of Carcinogens, Mutagens & Reprotoxins (CMR’s)

- Free from Substances of Very High Concern (SVHC’s)

- Reduced Environmental Hazards

300 Series Fast Hardener

400 Series Fast Hardener

3rd Party Certifications

| System | Hardener | DNV | Lloyd’s Register | RINA |

| 300er Serie | Spabond™ 335 | not certified | not certified | not certified |

| Spabond™ 340LV HT | ✓ Certified | not certified | not certified | |

| Spabond™ 345 | ✓ Certified | abgelaufen | not certified | |

| 400er Serie | Spabond™ 435 | ✓ Certification in progress | ✓ Certification in progress | not certified |

| Spabond™ 440 | ✓ Certification in progress | ✓ Certification in progress | not certified | |

| Spabond™ 445 | ✓ Certification in progress | ✓ Certification in progress | not certified | |

| Spabond™ 400FR | not certified | not certified | ✓ Certified |

Structural Fire Retardant Epoxy Adhesive

- Self-extinguishes following UL-94 type test (represents V0 classification)

- Low toxicity & halogen free

- Simple 3:1 mix ratio by volume

- Available with fast hardener

- Excellent gap filling properties

- Good thermal, mechanical & adhesive performance

- RINA Certified:

- Surface materials and floor coverings with low flame-spread characteristics

- Adhesives used in the construction of ‘A’, ‘B’ & ‘C’ class divisions

Mix Ratio – why has it changed?

The viscosity of the hardener component has a large impact on the sag resistance of the mixed system. Moving to a 3 : 1 mix ratio, reduces the amount of hardener and change in consistency of the mixed system. Allows us to have 2 hardeners for use with 3 resins with a sag resistance of 5 to 30mm.

Improved packaging concept

Correct Size Cartridge Boxes

Reduced waste & empty volume & more stable to prevent collapse in transit.

- Co-axial dispense & not side by side

- Ensure priming procedure is followed

- Existing dispensers can be used

- Up to 30% faster dispense

- Existing 900ml and 400ml dispensers can be used with minor modification (replacement of the hardener plunger)