Fiber composites offer exceptional properties that are difficult or impossible to match by traditional materials such as steel, aluminum or wood. Today, composites are used in nearly every high-performance dynamic component on land, sea and air. Fiber composites are what make it possible to develop and produce ultra-lightweight components that are protected against corrosion while being able to withstand the highest loads. The need to produce ever lighter and more effective components increasingly requires the use of these materials.

Benefits of fiber composite

In order to grasp and understand the full range of possibilities offered by modern composites, a good knowledge of the wide variety of individual materials and their proper processing is required. Here we provide an insight into the theoretical principles of composites technology, introduce the various materials and their properties, and describe the common processing techniques used to manufacture a wide variety of components from these materials.

Theory of composite materials

In its simplest form, a composite material is a composition of at least two material components whose clever combination results in a new material with mechanical properties that are fundamentally different from those of the two components it contains. In practice, these are usually a surrounding material (the so-called “matrix”) and a reinforcement in the form of a fiber that gives the matrix greater strength and stiffness. Composites assembled in this way can be divided into three main groups:

Polymer-matrix composites are the most widely used. They are also known under the generic term FRP (fiber-reinforced plastics) and consist of a matrix, always based on polymers, in which various fibers — such as glass, carbon or aramid — are embedded.

In the automotive industry and in aircraft construction, metal-matrix composites are increasingly being used, in which mostly silicone carbide fibers are embedded in an aluminum matrix. Composites with a ceramic matrix are used wherever very high temperatures are expected, such as in aerospace and military applications for jet engines. Short fibers (so-called “whiskers”) of silicon carbide or boron nitride are embedded in the ceramic matrix.

Polymer Matrix Composites

Resin systems such as epoxy or polyester have — on their own — limited uses in the manufacture of structural components. Their mechanical properties are quite low, for example compared to most metals. However, they also have some advantages over metals; in particular, their ability to be used to create almost any shape, even highly complex ones.

Materials such as glass, aramid and boron do have extremely high tensile and compressive strength. However, these properties can hardly be used in their “pure form”. If these materials are subjected to a tensile load, failure occurs far below the theoretical load limit due to minute defects on the material surface. Fibers are therefore made from these materials; in this way, the surface defects, which are equal in number, are distributed over a limited number of individual fibers. When these isolated fibers then fail under a tensile load, the rest remains intact and the material can much better display its properties. Nevertheless, the application of such fibers remains limited to absorbing tensile loads along the fiber direction, roughly comparable to the individual fibers of a rope.

Only when the fibers are embedded in a resin matrix does the full range of mechanical properties become available. The resin introduces the applied forces into the material and distributes them evenly to adjacent fibers. Surface damage caused by individual fibers rubbing against each other or impact on the workpiece surface is prevented, because each individual fiber is now fully embedded in the resin and fixed in position. High strength and stiffness, ease of shaping complex shapes, and the best resistance to weathering — all combined with a low, specific weight; create composites that are far superior to metals in many applications. Because polymer-matrix composites always combine a resin with one or more types of fibers, the resulting properties of the material are a result of the properties of the fibers and the resins as individual materials.

The fiber volume fraction depends primarily on the manufacturing process. Since the properties of the fiber are superior to those of the resin in most respects, the general rule is that the higher the fiber content in a laminate, the better the mechanical properties. In practice, this rule is limited by the requirement that really all fibers must be completely enclosed by resin; if this is not the case (“dry laminates”), defects occur in the form of extremely fine air pockets that can lead to failure under load. Depending on the processing method selected, such flaws vary in severity.

In a typical hand laminate for boatbuilding, fiber volume fractions of about 30–40 % are found. In the high-end sector, e.g. in the manufacture of aircraft parts, values of up to approx. 70 % can be achieved. The arrangement of the fibers in the composite is also of great importance, since all fibers exhibit their highest strength parallel to the fiber direction (0°). Quite unlike isotropic metals, the properties of a composite material are therefore highly anisotropic, i.e. particularly pronounced in one direction. Fracture tests of a workpiece with differently oriented force application lead to completely different results. It is therefore of utmost importance for the successful utilization of the material-typical advantages that the direction and intensity of the expected loads are already known in the design phase and are taken into account accordingly. In this way, laminates can be optimized according to the load situation; simply put, fibers are placed only where loads are expected to occur, thus avoiding unnecessary oversizing in areas or directions subject to less or no load.

Another important difference to metals is the definition of the material properties by the processor. Anyone who processes metals can no longer change their properties, once given, to the advantage or disadvantage of the product to be manufactured. The situation is quite different with composites: Here, the material is created only in the course of manufacturing a component; its quality depends to a large extent on the quality of the work of the individual processor. By acting carefully and responsibly, he can make a decisive contribution to ensuring that the properties expected in theory are actually achieved. On the other hand, his negligence or ignorance can also lead to the failure of entire assemblies!

Strains & Loads:

Each material is subjected to four different loads in a finished structure: Tensile, compressive, shear and bending loads.

Tensile load

The figure shows a tensile load acting on a composite component. Its resistance to such a load depends essentially on the stiffness and tensile strength of the fibers used.

Compressive load

Here, too, the strength of the composite depends on the properties of the fibers, with the difference that the resin component resists compression much better than tension. The most important task of the resin in this case, then, is to hold the fibers together in their arrangement.

Shear load

This force attempts to displace the individual fibers against each other. This is where the resin plays the essential role; distributing the force over as large an area as possible. The resin must therefore not only have very good mechanical properties, but also good adhesion to the enclosed fibers. ILSS (Interlaminar Shear Strength) refers to the strength in a multilayer laminate.

Bending load

Bending forces represent a combination of the three aforementioned loads; the upper region of the component is under compression, the center experiences shear loading, and the lower region is pulled.

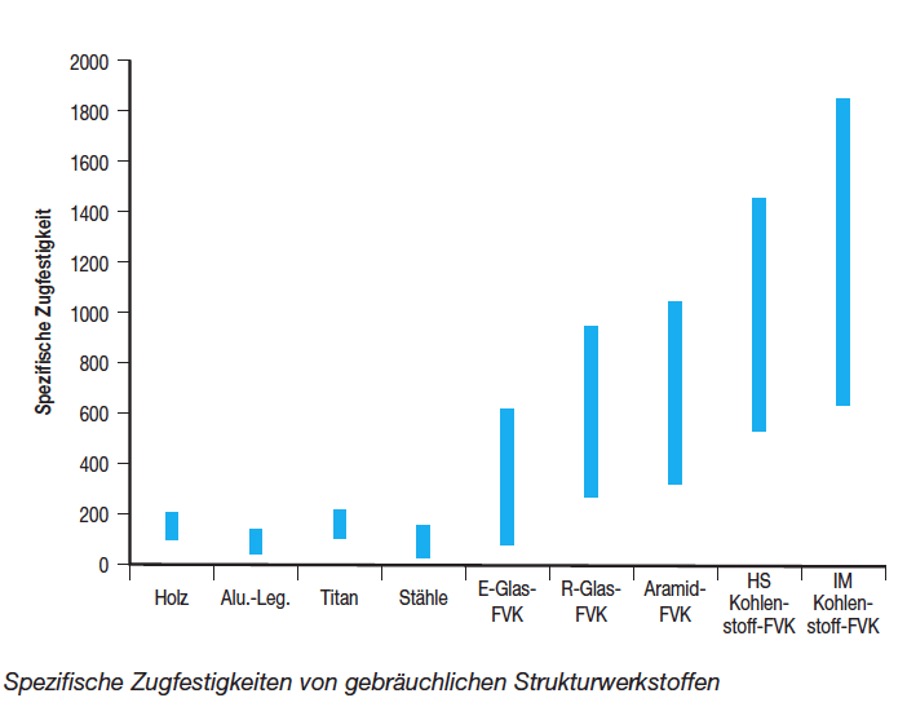

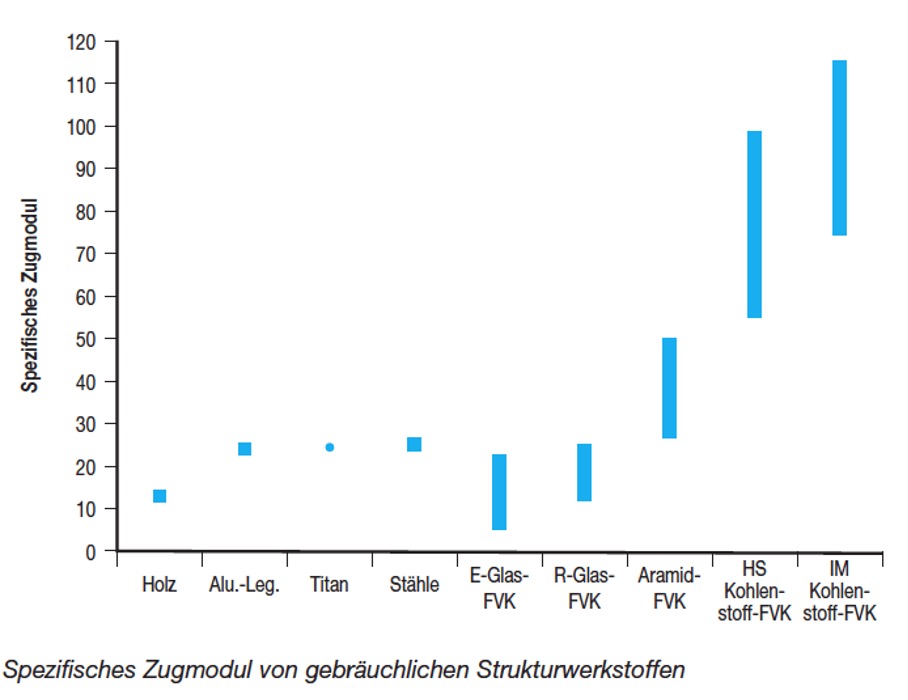

Comparison with other structural materials

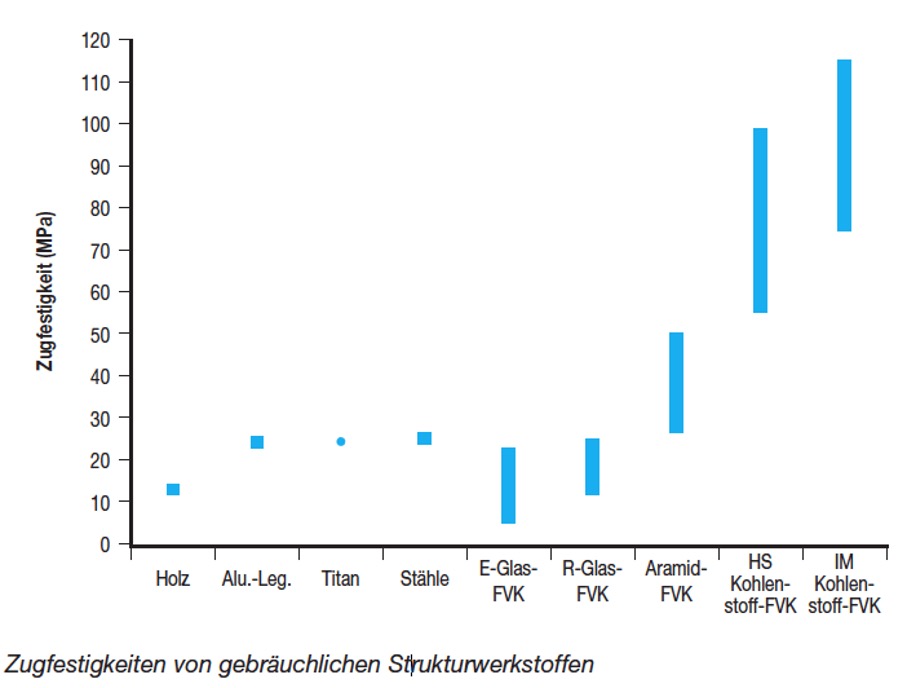

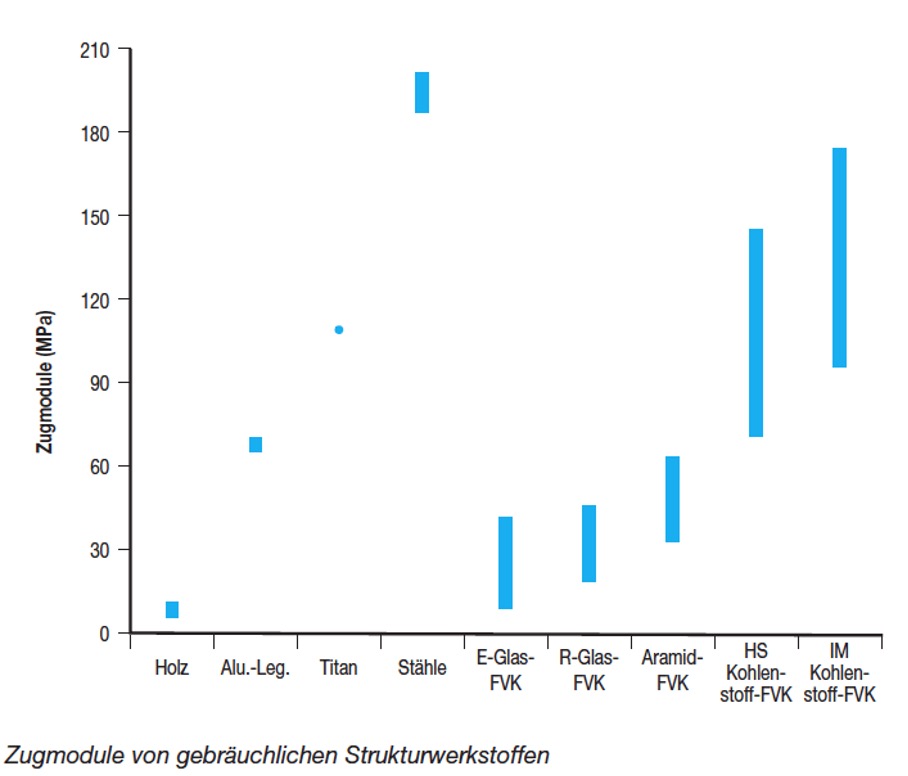

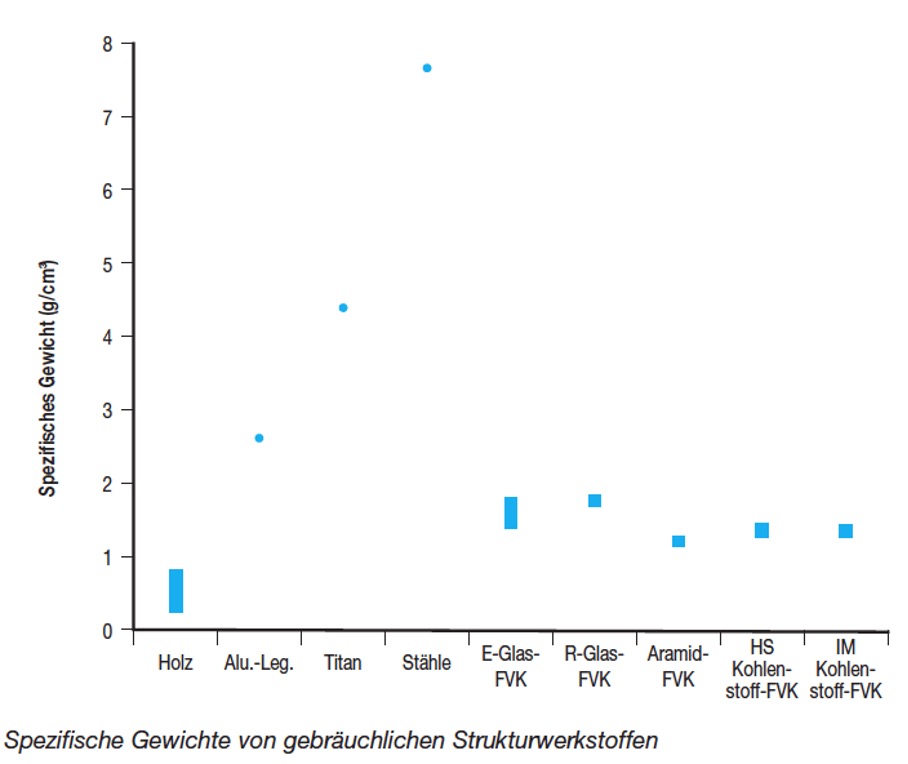

Due to the factors described above, there is a wide range of possible mechanical properties that a fiber composite material can exhibit. Even if only one type of fiber is considered, the properties can vary by a factor of 10 as a result of different fiber proportions and orientations! In the following, these properties are compared with each other; the lowest values in each case are based on simple manufacturing processes and material forms (e.g. fiber injection processes), the higher ones on high-end processes (e.g. unidirectional laminates from autoclaves) from aerospace. Values such as strength and stiffness of other materials, such as aluminum alloys, are also listed for comparison.

The above graphics impressively show the range of mechanical properties that fiber composites can exhibit. They can be summarized with the term: “High strength and stiffness at low weight”. These properties are what make fiber composites so extremely interesting for many uses in structural applications. In particular, of course, this applies to applications in which large masses have to be accelerated and brought to a standstill again from an economic point of view, i.e. in the field of transportation in the broadest sense (airplanes, ships, cars, trains, etc); here, mass reduction while ensuring (safe!) strength plays the decisive role.

The following graphs show the strength properties of the various materials and material combinations in relation to their weight; these are therefore specific values. In contrast, the above graphs 6 and 7 show absolute values, where as a rule the strongest material is also the heaviest.