Table of contents

Sven Kraja and his experience with Ampro

“I have been a boat builder for 30 years and have worked with epoxy all my work life.

What a difference now with the new Ampro system: no sticky surfaces, the sandpaper can be used many times longer than before and the long recoat period makes the work relaxed and with very good results. Also the final coating with the CLR hardener delivered a super gloss level on the checkerboard carbon!

A really big step forward — my new favorite is Ampro!”

Sven Kraja

Boatbuilder and sailmaker

Frog Sails Schleswig

World and European Champion in Beach Sailing

Why you should choose Ampro!

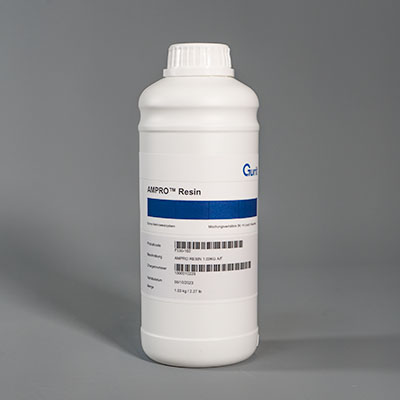

Gurit’s AmproTM is the first choice for professionals for bonding, laminating, coating and filling! It is very easy to use, has very low toxicity and is also solvent-free.

What is a multipurpose epoxy system?

This is a multi-purpose epoxy system of the latest generation from Gurit. It is an easy-to-use system that can be used for bonding, coating, laminating and filling.

Coating — Bonding — Filling — Laminating

What makes AMPRO™ the market-leading multi-purpose system?

This multi-purpose epoxy is an easy-to-use system with a wide range of applications, which has the following properties:

- Professional: The boat and marine builder’s choice for bonding, laminating and filling.

- Safer: Reduced toxic ingredients with fewer dangers

- Stronger: More flexible resin matrix ideal for working with wood

- Non-tacky: No armin redness after curing and no smearing of sandpaper

- Waterproof: AMPRO™ SILICA has been optimized for marine applications

- Wide recoat buffer: open for up to 4 days without sanding

- Faster: Improved curing at low temperatures down to +5°C.

- Gloss: Improved gloss level during coating with almost defect-free surface

- Cardboard packaging: Less plastic

- More sustainable: Accredited bio-based option with plant-based ingredients

- Simpler: Four different system with same mixing ratio 3:1.

What does bio-based mean?

AMPRO™ was developed using the same approach as the award-winning Ampreg™ 3X Series, which focuses on user health and safety through careful selection of base chemicals.

The new low toxicity resin matrix is CMR and SVHC free. Gurit carefully selects the chemicals used to ensure the lowest possible risk of future reclassification — ensuring the safety of our products and the health and safety of end users. This approach is part of Gurit’s philosophy.

Focus on health and safety

Our manufacturer Gurit is trying to avoid the dependence on petroleum-based chemicals by using alternative raw materials with sustainable plant-based origins. These sources are by-products of the food chain and are converted to epoxy chemicals and used to formulate AMPRO™ BIO. Gurit’s unique bio-based technology delivers excellent performance and is currently the only “OK bio-based” system certified by TÜV:

AmproTM — Products and typical applications

Ampro | One system, different applications

AMPRO — THE ALLROUNDER

This is the improved successor to SP106, which has proven itself for many years. It is a multi-purpose epoxy system for gluing, coating and filling and is particularly suitable for the production of wood-epoxy composite components. For highly transparent coatings the hardener Ampro CLR is recommended.

AMPRO BIO — THE SUSTAINABLE

This multi-purpose epoxy system is made with over 40% organic content from pressed coconut shell oil, making it extremely sustainable. Together with flat fibers and Kerdyn PET foam made from recycled bottles, this is a sustainable alternative. The hardeners are the same as for the Ampro system.

AMPRO CLR — THE COATING

This is the improved successor to SP320 and SP115, which have proven themselves for many years. It is an extremely clear multi-purpose epoxy system with improved UV properties and is particularly suitable for coating natural wood and building surfboards. The resin base is Ampro resin, the hardener is specially formulated.

AMPRO SEAL — THE SEALANT

This is the sealer based on Ampro hardeners and the improved successor of the solvent-based Eposeal 300. As it is solvent-free, it has an extremely short recoat interval and is therefore considerably faster to apply. The resin base is specially formulated, the hardeners correspond to the AmproTM CLR or standard hardeners.

Which Ampro for which application?

The product consists of exchangeable resins, mixable hardeners and additives for many applications. The following table takes you step-by-step through the options for choosing the right AMPRO™ system.

The choice of the right system

| AMPRO™ | AMPRO™ CLR | AMPRO™ BIO | AMPRO™ SEAL | |

| Low working temperatures | ✓ | ✓ | - | - |

| Clear coating | - | ✓ | - | - |

| Wood coating | ✓ | ✓ | ✓ | - |

| Bio-based ingredients | < 10% | - | 40 — 60% | 40 — 60% |

| Sealing and priming porous surfaces | - | - | - | ✓ |

| Filling, spackling or bonding | ✓ | ✓ | ✓ | - |

| Filler materials | - | - | ✓ | ✓ |

The choice of hardener speeds

| Fast | Slow | Extra-Slow | |

| Open time with brush at 20°C | 1- 2 hours | 4 — 5 hours | 5 — 6 hours |

| 50g Pot life in air at 20°C | 30 minutes | 1 hour | 1,5 hour |

The choice of the right fill material

| Micro Balloons | Glass Bubbles | Micro Fibres | AMPRO Silica | ||

| Filling & spackling | Easy to sand, fill and coving for optical wood applications | ✓ | - | - | ✓ |

| Waterproof or inexpensive putties for all applications | - | ✓ | - | ✓ | |

| Hard surface coating on surfaces and edges | - | ✓ | - | ✓ | |

| Bonding | General bonding of soft woods, color brown | ✓ | - | - | ✓ |

| General bonding of soft woods, color white | - | ✓ | - | ✓ | |

| Structural bonding of wood or composite, opaque color | - | - | ✓ | ✓ | |